warp let-off systems

In order to control the weaving process precisely, an equal and repeatable warp tension is of high importance.

Using state-of-the art, industry-proven components, we offer budget-friendly warp-let-off systems to improve your process

Electronically controlled warp let-off systems help you to eliminate human error and make process results repeatable.

We offer custom-made solutions to fit your needs!

General

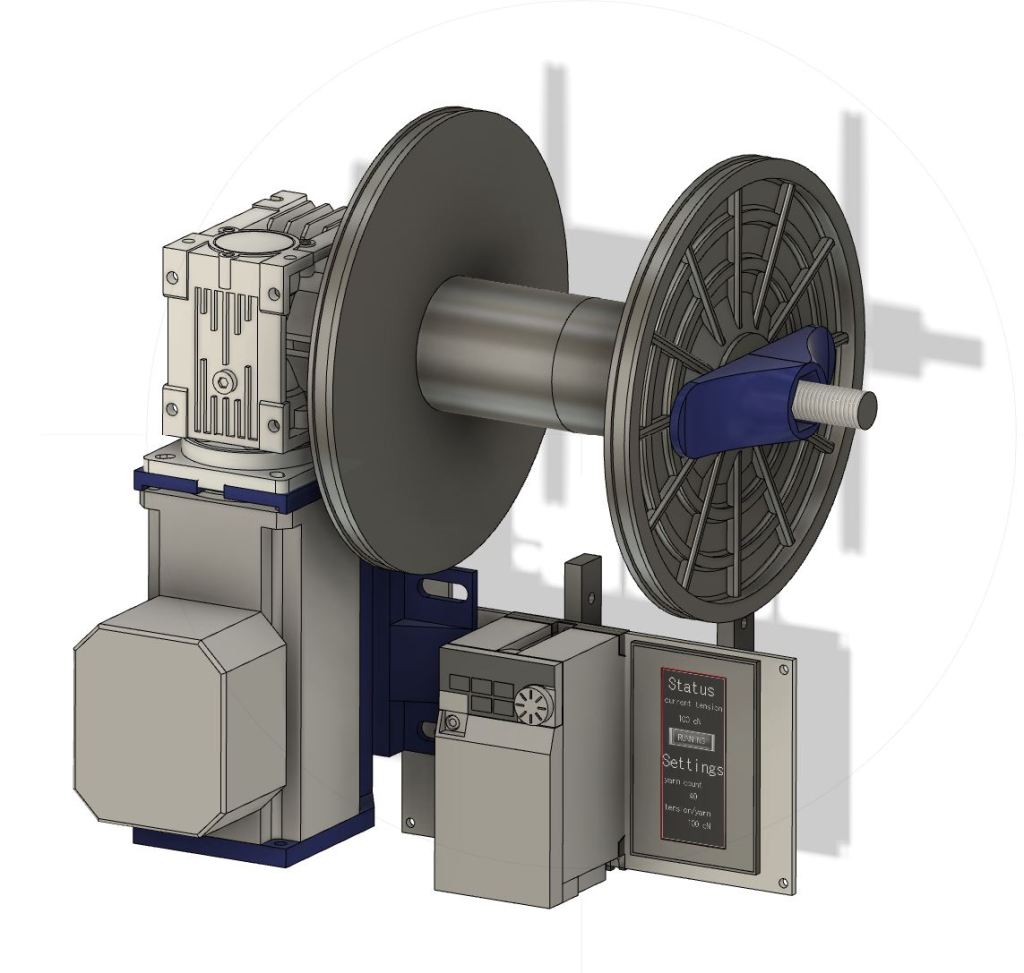

- warp let-off control system to execute the unwinding of a textile web under tension control and with visualization of process parameters

- inverter/HMI combination to control with

- state of the art/industry standard variable frequency drive for exact motion control and regulation (through internal programmable logic controller)

- State of the art/industry standard display for the visualization of

- yarn tension

- inverter/control system alarms

- programmable tension curve

- user interface in national language

- input parameters/adjustments:

- yarn count

- required tension

- regulation parameters

Features

- power supply 230V or 480V

- Mitsubishi inverter and HMI

- loadcell tension control

- ready-to-use (software pre-programmed on inverter)

- customized changes to visualization possible on request

- easy-to-use maintenance and troubleshooting page

- lifetime check for capacitors and relay

- minimal installation effort

- documentation included:

- system overview

- conversion instruction

- troubleshooting manual (error codes and solutions)

- electrical diagram

- loom interfacing

- tension setpoint

- alarm output