Batch winder control systems

Batch winders are mechatronic systems that form rolls of web products (e.g. textiles).

While the mechanical parts often could endure for ages, the electronic control suffers failures before that.

Spare parts are often obsolete or come at high costs, complete new winders might be bought due to missing alternatives.

If you are familiar with this situation and looking for a solution, check out our versatile batch winder control system.

We are able to offer your customized retrofits to find an economical and satisfying solution

Regardless of the type of regulation (dancer/loadcell) or the previously used motor/supply voltage. We offer completely compatible custom-made solutions to fit your needs!

General

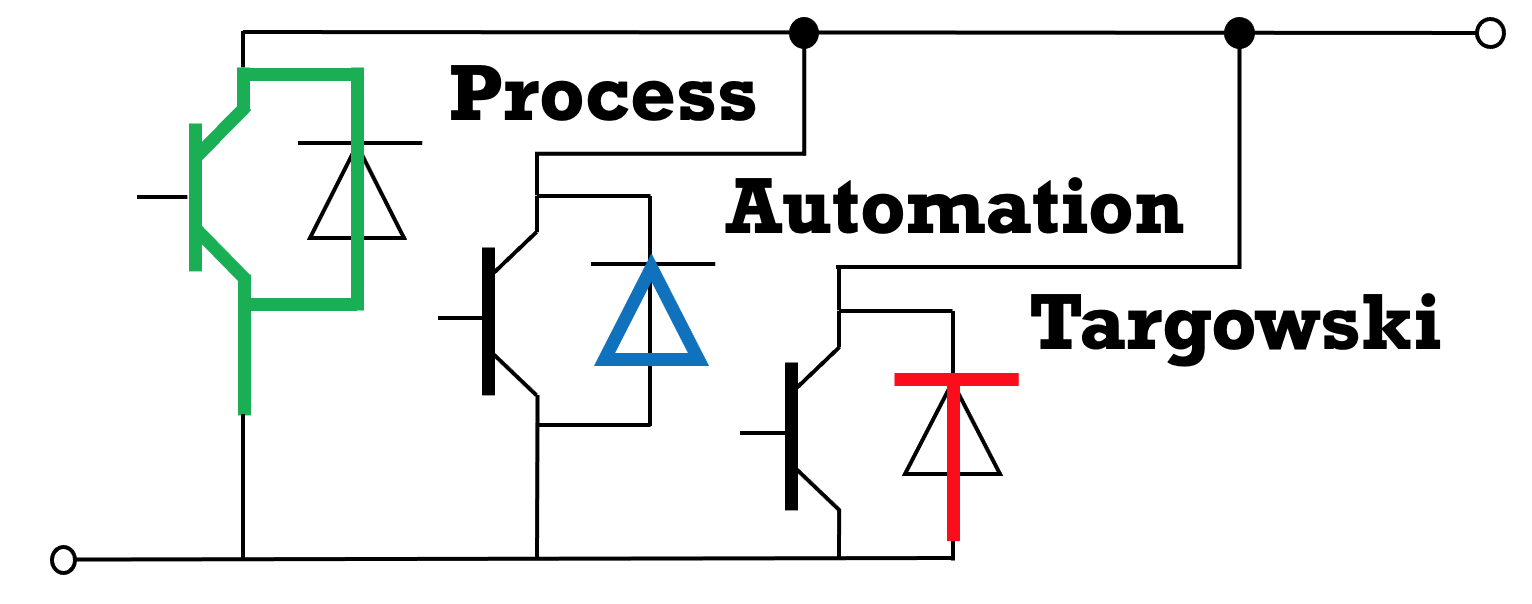

- Batch winder control system to execute the winding of a textile web under tension control and with visualization of process parameters

- Replacement of previous inverter/HMI control with

- State of the art/industry standard variable frequency drive for exact motion control and regulation (through internal programmable logic controller)

- State of the art/industry standard display for the visualization of

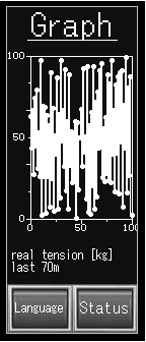

- Fabric tension (in kg)

- Current roll length and meter reset

- Inverter/control alarms

- Programmable tension curve

- User interface in national language

Features

- power supply 230V or 480V

- frequency 50 or 60Hz

- Mitsubishi inverter and HMI

- loadcell or dancer tension control

- ready-to-use (software pre-programmed on inverter)

- customized changes to visualization possible on request

- easy-to-use maintenance and troubleshooting page

- lifetime check for capacitors and relay

- only minimal conversion effort (0,5 working hour of electrician)

- reusing of cabinet, motor, buttons/switches, relays and cabinet openings of previous used batch winder control system.

- installation of inverter by supplied adapter plate and terminals/mountings.

- documentation included:

- system overview

- conversion instruction

- troubleshooting manual (error codes and solutions)

- electrical diagram

| BWCS I | BWCS II | BWCS III | BWCS IV | |

|---|---|---|---|---|

| characteristic | „precise winding process control with manifold adjustable process parameters“ – our most versatile product | „smooth tension control and easy setup of the main winding process parameters“ – our alround solution | „reliable and repeatable winding process results – while using state-of-the-art drive technology“ – our budget-friendly solution | „combining the precision of a loadcell regulation with the energy-saving advantages of an IE5 class motor“ – our most innovative product |

| control input | load cell | spring-loaded dancer arm with potentiometer | weight-loaded dancer arm with potentiometer | load cell |

| drive technology | 3 phase AC motor | 3 phase AC motor | Sensorless Servo motor | Sensorless Servo motor |

| control interface | HMI | HMI | customized inverter parameter unit | HMI |

| features | – meter count input – tension curve setting – encoder feedback control selectable – customized language package – 24VDC supply unit included in inverter – motor protection input – alarm output to loom | – meter count input – tension curve setting – encoder feedback control selectable – customized language package – alarm output to loom | – meter count input – alarm output to loom | – meter count input – tension curve setting – customized language package – 24VDC supply unit included in inverter – alarm output to loom |

HMI screens